Barcelona-based Peris + Toral Arquitectes has completed 43 Viviendas Sociales, a social housing project in Ibiza that shows how design and material choices can reduce environmental impact. Passive strategies and a modular layout lower energy use, while compressed earth blocks (CEBs) replace concrete to cut carbon emissions.

Drawing on vernacular knowledge and systems thinking, the project offers a flexible model for sustainable housing tailored to the Balearic climate but adaptable elsewhere as earthen construction gains traction.

Sustainability in this project goes beyond materials—it’s about how they’re used. Through careful calibration of thickness, mass, and layout, the design meets environmental, acoustic, and thermal goals while maintaining a raw and honest expression.

Passive design for Mediterranean living

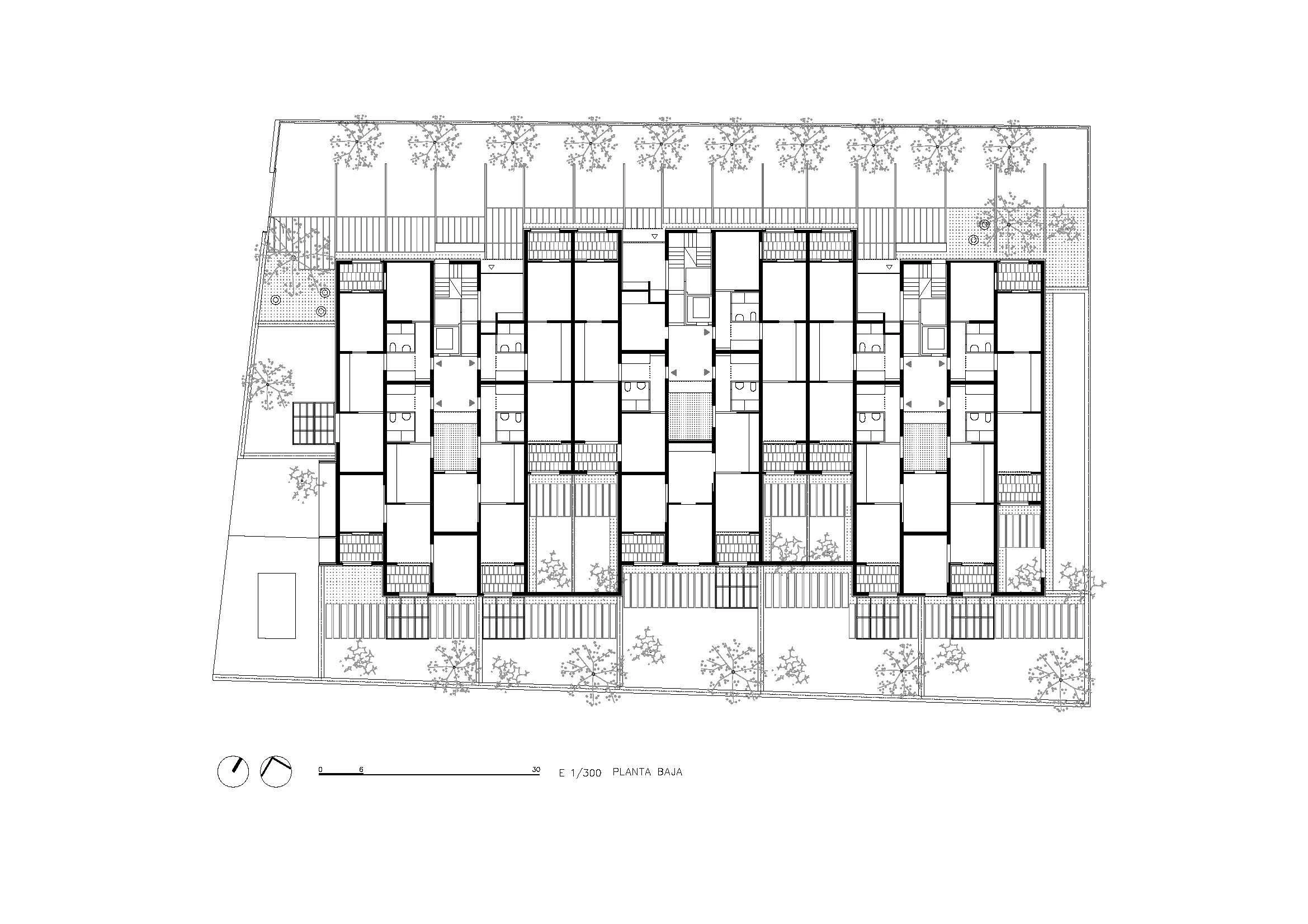

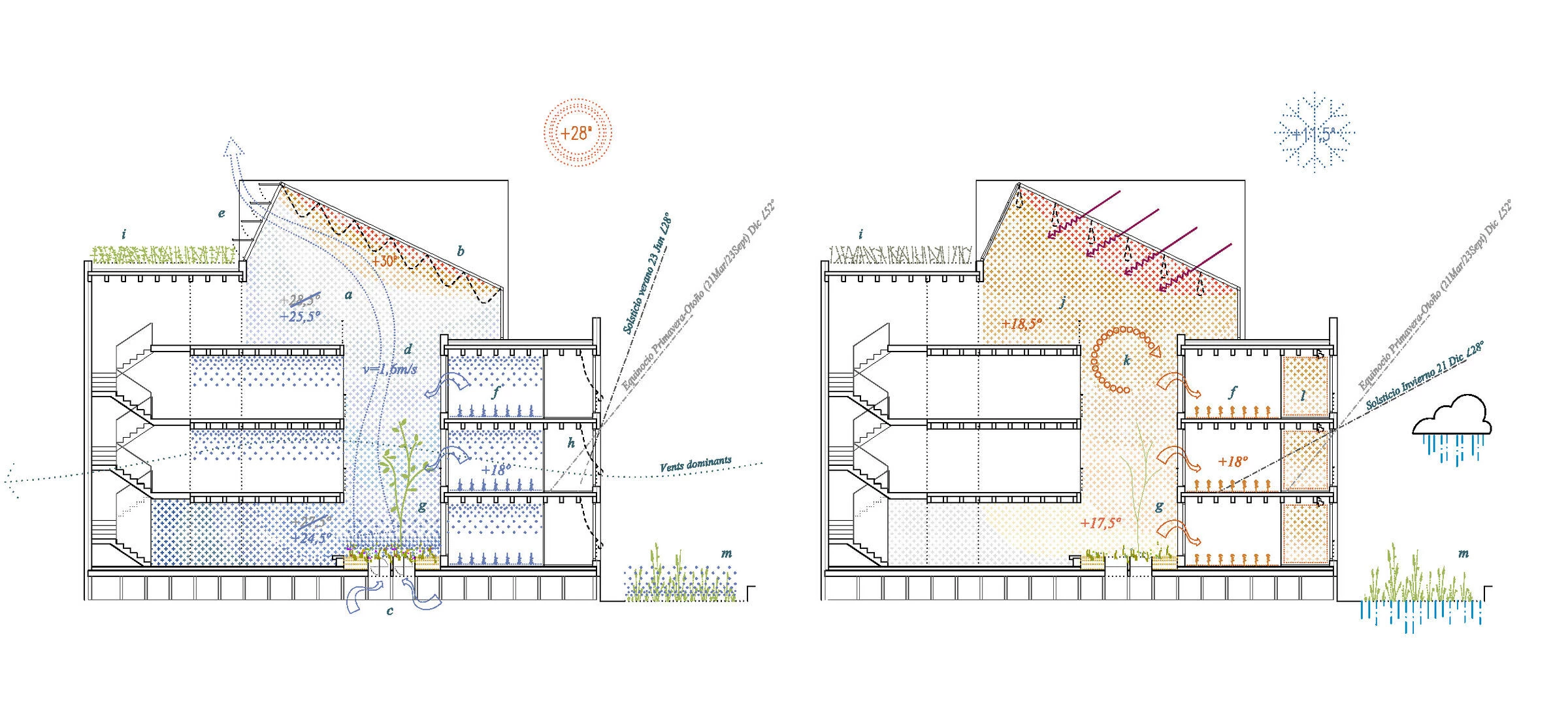

Located near Ibiza’s southern coast, the building is oriented to take advantage of sea breezes, enabling natural cross-ventilation throughout all 43 residential units. The layout eliminates internal corridors, allowing each module—measuring 12 square meters—to connect directly to its neighbor through large-format doors. These connections encourage airflow and allow the structure to breathe. Larger apartments are dual-oriented to the north and south, while smaller units open onto central patios, ensuring that all benefit from natural ventilation.

Thermal comfort is maintained without mechanical heating or cooling. In summer, a covered central courtyard acts as a solar chimney, drawing hot air up and out of the building. In winter, it functions as a protected atrium. The complex also integrates semi-outdoor spaces like winter gardens and terraces, buffering internal rooms from external temperature fluctuations and direct sunlight. These design moves reduce reliance on energy-intensive systems and create a naturally regulated living environment.

Compressed earth blocks as structure and envelope

Rather than rely on concrete or steel, Peris + Toral turned to compressed earth blocks as the primary structural and partition material. Learn more about this through Archello's dedicated detail article: Detail: Compressed Earth Block Walls of 43 Viviendas Sociales, Ibiza.

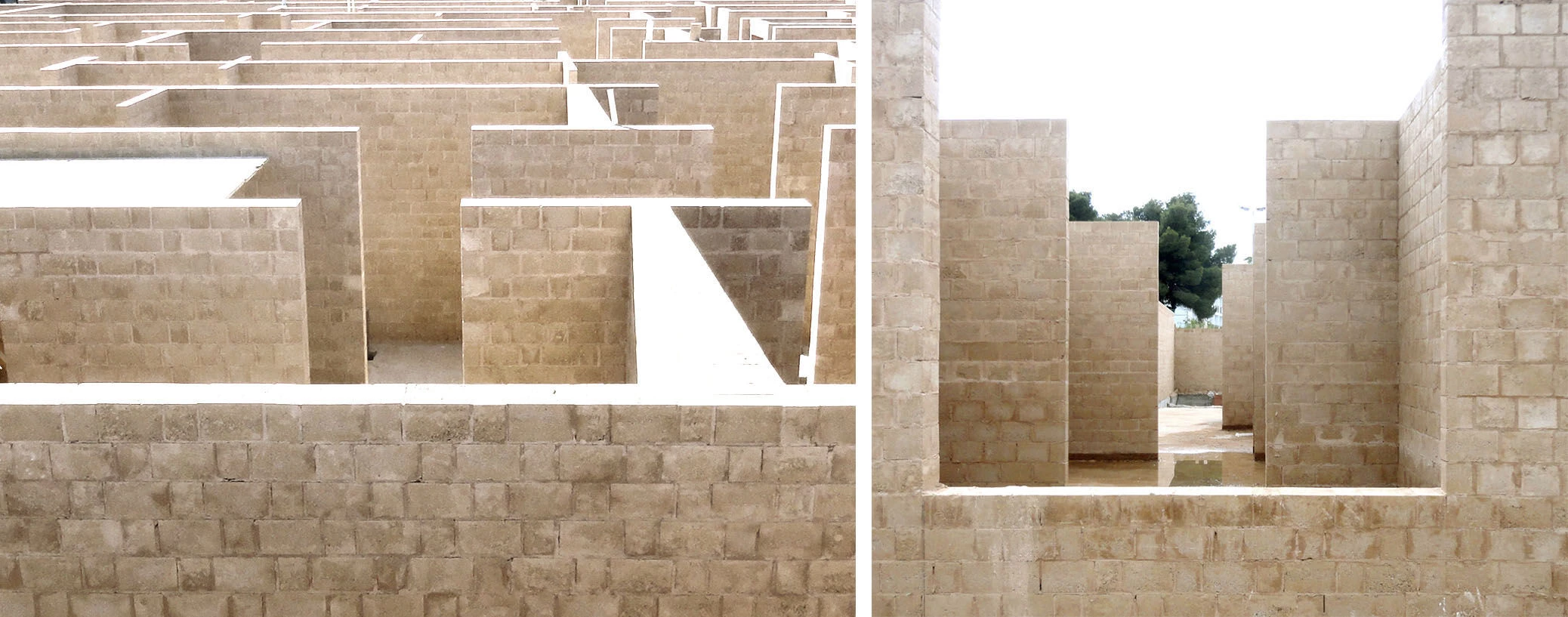

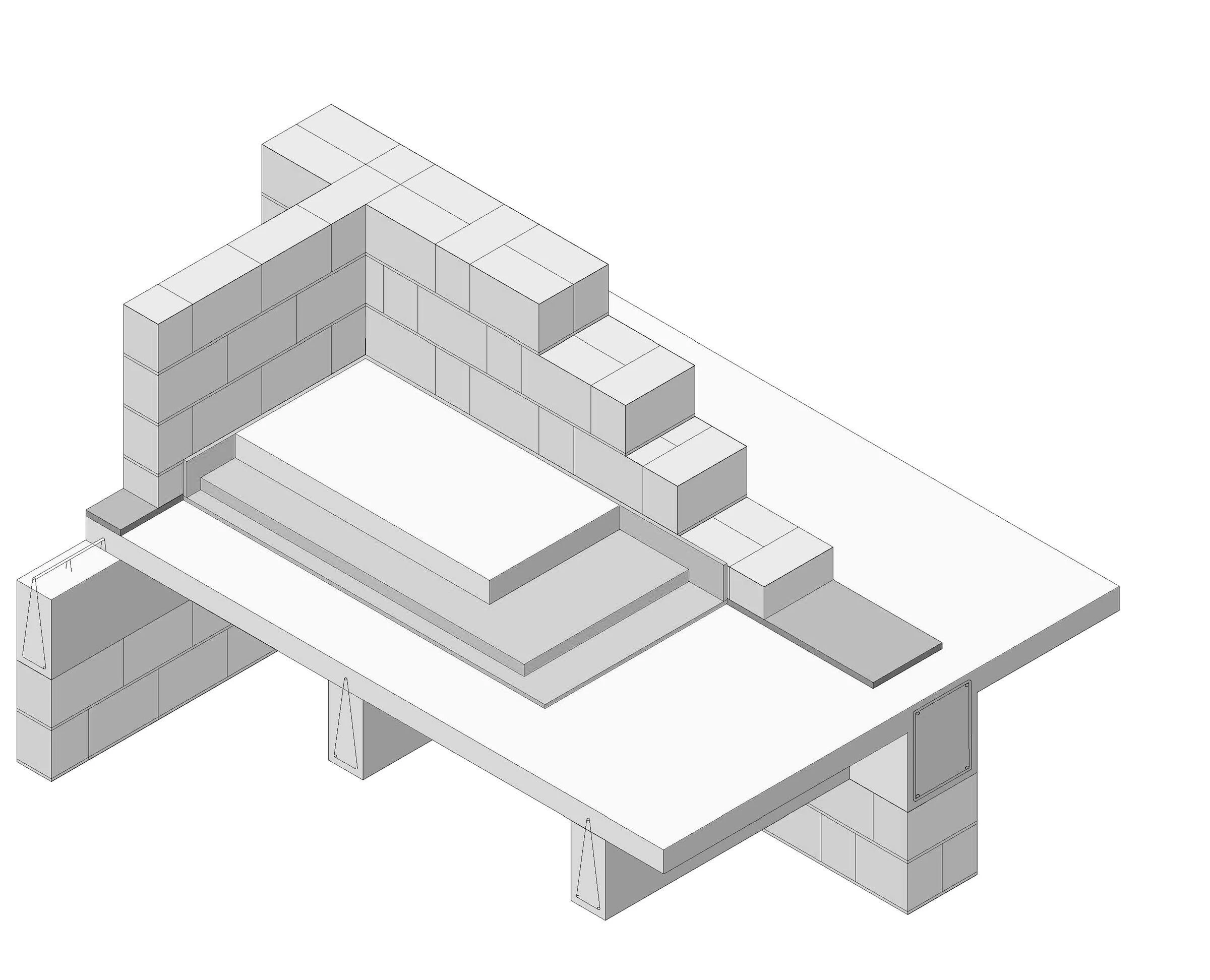

The load-bearing walls are built from 20 cm thick CEBs manufactured in Catalonia and shipped to the site. Each block, made from a mix of local soil, clay aggregate, and lime, weighs less than four kilograms—light enough to be handled manually. This not only avoided heavy machinery but also accelerated construction.

Earth was chosen for its high thermal mass and ability to regulate humidity—two critical factors in Ibiza’s hot and humid summer climate. The material absorbs moisture from the air and buffers temperature swings, helping keep interiors comfortable. To further reduce emissions, the architects avoided reinforcing the walls with steel. Instead, the wall system relies on mass and compression alone. All openings are taken up to the floor slab above, removing the need for lintels or additional structural elements.

The structure is built using the TAPIALBLOCK® system 10x20x10 centimeter blocks by Fetdeterra, assembled with lime-based mortar also provided by Fetdeterra. The load-bearing walls are 20 cm thick and arranged using a Flemish bond pattern. Separation walls between residential units are also 20 centimeters thick, providing sufficient mass to meet the CTE_HR (Spanish Building Code for sound insulation) requirements. Interior partition walls within the same unit are 10 centimeters thick.

Heat gain is increased through solar radiation captured in sun-facing galleries. Air renewal is achieved via solar atriums, where air is preheated by the greenhouse effect, raising interior temperatures through convection. The combination of external insulation and the thermal inertia of the TAPIALBLOCK® earthen walls helps retain comfortable indoor temperatures through conduction.

Acoustic and thermal performance with minimal material

One of the project’s greatest challenges was achieving acoustic separation between apartments without doubling wall thickness. By using a single 20 cm CEB wall with a density of 2000 kg/m³, the construction meets soundproofing standards while minimizing material use. Interior partitions use thinner 10 cm blocks, balancing structural needs with spatial efficiency.

The external envelope includes natural cork insulation and a protective white lime plaster to guard against erosion. Inside, the CEB walls are left exposed. To seal joints and improve acoustics, a fine clay plaster—matching the color and texture of the blocks—was applied and polished. This finish reflects light into the units while preserving the hygroscopic properties of the earth.

Lightweight concrete floors with a low-carbon strategy

The floors were initially designed in timber to reduce emissions but were ultimately built using a hybrid system of prefabricated concrete beams topped with a thin slab. This system balances structural inertia with reduced material use. By optimizing the dimensions and bonding method, the team achieved the equivalent performance of a 10 cm solid slab with significantly less concrete. The 25 cm total buildup translates to a 66% reduction in concrete volume compared to conventional slabs.